Profitability hinges on operational efficiency. However, outdated manual processes, fragmented inventory systems, and labour shortages are holding many businesses back. The pressure to meet customer expectations for faster, more accurate order fulfilment is higher than ever.

Warehouse automation isn’t just about upgrading technology—it’s about transforming your operations to improve your bottom line. This guide explores the latest trends in warehouse automation, why it’s crucial for growth, and how warehouse management software can help you future-proof your operations.

The State of Warehouse Automation in 2025

In 2025, warehouse automation is no longer a luxury—it’s a necessity. The rise of e-commerce has driven demand for faster, more efficient warehouse operations. Online retail sales of physical goods are expected to approach $1.4 trillion, increasing the need for warehouse space and services.

However, 90% of warehouse operators report that cost-cutting measures are essential to balance the demand for more space and services with the challenges of hiring and retaining qualified staff.

To stay competitive, modern warehouses are shifting from traditional storage roles to value-added services, order customisation, and rapid flow-through processes aligned with just-in-time inventory principles. Automation is at the core of this transformation.

Key Challenges in Warehouse Management

Common challenges in warehouse operations include:

- Insufficient Warehouse Space: As demand for faster order fulfilment grows, space constraints are becoming a significant issue. Automation helps maximise existing space by optimising inventory storage and reducing unnecessary stock.

- Inefficient Inventory Operations: Manual inventory tracking is prone to errors, leading to stock discrepancies and delayed order fulfilment. Automation enhances accuracy and visibility, preventing overstocking and stockouts.

- Labour Shortages: Finding and retaining skilled warehouse workers is increasingly difficult. Automated systems reduce dependency on manual labour, improving productivity and reducing costs.

- Cost Pressures: The need to cut costs while maintaining operational efficiency is a constant challenge. Automation minimises manual tasks, reducing operational expenses and maximising profit margins.

Trends Shaping Warehouse Automation in 2025

The landscape of warehouse automation is evolving rapidly. Here are the top trends driving this transformation:

1. Big Data and Analytics: Driving Informed Decision-Making

Real-time data is revolutionising warehouse management by enabling informed decision-making and optimising operations. Leveraging data analytics allows businesses to:

- Identify Sales Trends: Prevent stockouts and overstocking by predicting demand accurately.

- Improve Decision-Making: Use data-driven insights to optimise inventory levels and reduce waste.

- Track Key Performance Indicators (KPIs): Gain greater operational control by monitoring critical metrics such as order accuracy and fulfilment times.

- Enhance Shipment Visibility: Improve carrier performance and customer satisfaction with real-time tracking.

2. Micro-Fulfillment Centres (MFCs): Enhancing Delivery Speed and Efficiency

MFCs are changing the way businesses handle inventory and fulfilment by bringing products closer to customers. This approach enables:

- Faster Delivery Times: Shorten last-mile delivery, enhancing customer satisfaction.

- Reduced Shipping Costs: Lower transportation expenses by optimising distribution networks.

- Scalable Operations: Expand fulfilment capabilities without the need for massive warehouse spaces.

3. AI and Robotics: Revolutionising Warehouse Operations

Artificial intelligence (AI) and robotics are at the forefront of warehouse automation. Businesses are leveraging these technologies for:

- Smart Picking and Packing: AI-driven robots streamline order fulfilment, minimising human error and speeding up processing times.

- Predictive Maintenance: AI predicts equipment failures before they occur, reducing downtime and maintenance costs.

- Automated Quality Control: Machine learning algorithms ensure product consistency and accuracy, reducing returns and enhancing customer satisfaction

4. Automated Guided Vehicles (AGVs) and Drones: Increasing Accuracy and Safety

AGVs and drones are enhancing efficiency by automating repetitive tasks and improving safety. Benefits include:

- Automated Material Handling: AGVs transport materials within the warehouse, reducing the need for manual labour.

- Inventory Accuracy: Drones automate cycle counting and inventory scanning, minimising human error.

- Enhanced Safety: By reducing human interaction with heavy machinery, AGVs and drones improve workplace safety.

Why Warehouse Automation is Crucial for Business Growth

Warehouse automation isn’t just about technology—it’s about strategic growth. Automation is essential because it:

- Optimises Inventory Management: Prevents overstocking and stockouts by ensuring accurate inventory tracking and efficient stock replenishment.

- Enhances Order Fulfilment Accuracy and Speed: Automated picking, packing, and shipping reduce errors and improve order accuracy, enhancing customer satisfaction.

- Reduces Operational Costs: Automation minimises labour costs, reduces manual errors, and maximises resource allocation, improving profit margins.

- Improves Customer Satisfaction: Real-time inventory visibility enables accurate order updates and faster delivery, leading to better customer experiences.

Implementing Warehouse Automation

Successful warehouse automation requires a strategic approach. Here’s how to get started:

- Assess Current Operations: Identify pain points such as stock discrepancies, labour shortages, or fulfilment delays.

- Set Clear Automation Goals: Define measurable objectives like reducing order fulfilment time, minimising stock discrepancies, or increasing productivity.

- Invest in the Right Technology: Evaluate ERP systems, AI tools, and robotics tailored to your business needs.

- Train Your Team: Equip employees with the skills needed to operate new systems and adapt to automated workflows.

- Monitor and Optimise Continuously: Use performance data to identify areas for improvement and optimise automated processes for maximum efficiency.

The Role of MYOB Acumatica in Warehouse Automation

MYOB Acumatica, a powerful cloud ERP solution, is redefining how businesses approach warehouse automation by offering an all-in-one warehouse management software (WMS) that drives efficiency, reduces errors, and enhances decision-making.

Here’s how MYOB Acumatica enhances warehouse management:

1. Real-Time Inventory Management

MYOB Acumatica offers end-to-end inventory management with real-time stock tracking, ensuring businesses maintain optimal stock levels. By automating replenishment, it prevents overstocking and stockouts, maximising order fulfilment accuracy.

- Accurate Stock Insights: Gain visibility into inventory turnover, slow-moving items, and low stock levels, enabling informed decision-making.

- Barcode and RFID Integration: Verify orders as they are picked and packed, reducing costly mistakes and ensuring order accuracy.

2. Seamless Integration and Visibility

This warehouse management software connects inventory, sales, purchasing, and financials on a unified platform, eliminating data silos. This integration provides comprehensive visibility across all business functions for better decision-making.

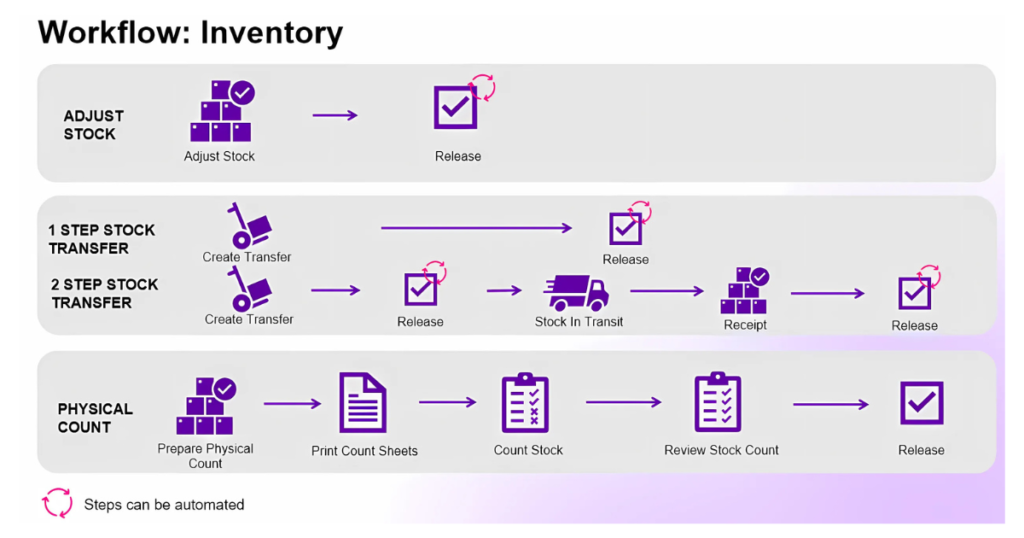

- End-to-End Management: Automate workflows from inventory movement to order fulfilment and stock replenishment.

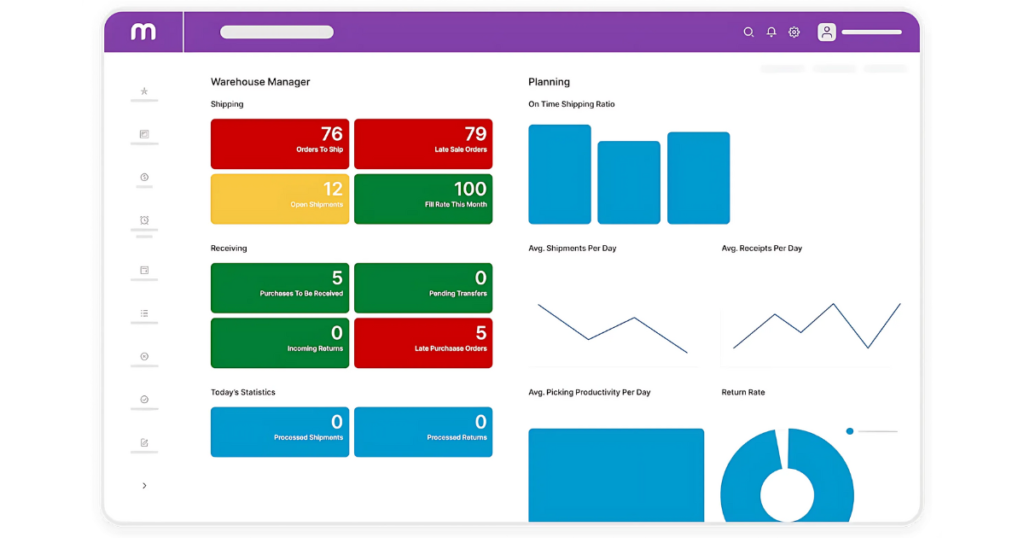

- Cross-Departmental Collaboration: Customisable dashboards offer role-specific insights, enhancing collaboration between warehouse and purchasing managers.

3. Automated Workflows for Efficiency

MYOB Acumatica automates key tasks, reducing manual input and minimising errors in order processing, invoicing, and inventory updates. This streamlines operations, improves productivity, and enhances profitability.

- Packing Automation: Integrate with printers and digital scales to automatically print labels and packing slips, ensuring accuracy in order fulfilment.

- Customer Alerts and Notifications: Keep customers informed with real-time order updates, shipping statuses, and tracking information.

4. Advanced Reporting and Analytics

With MYOB Acumatica’s cloud ERP and warehouse management software, businesses gain real-time insights with detailed reports and dashboards, enabling actionable decision-making. It tracks key performance metrics, including sales orders, shipping efficiency, staff productivity, and return rates.

- Detailed Reports and Data: Monitor profitability, identify growth opportunities, and make data-driven decisions with comprehensive reporting tools.

- Tailored Dashboards: Customise dashboards by role to provide relevant insights for different departments, ensuring informed decision-making at every level.

Modernise Your Warehouse with MYOB Acumatica

AlphaBiz Solutions, a recognised MYOB Partner, offers MYOB Acumatica to transform your warehouse operations. By connecting inventory management, order fulfilment, and customer communication on a single platform, this warehouse management software automates workflows, reduces costs, and enhances productivity.

Ready to see it in action? Book a complimentary demo with us today and discover how warehouse automation can boost your bottom line.